Machine screws are essential fasteners used in machinery and mechanical devices. They securely hold parts together, ensuring structural integrity and safety. Proper size selection is crucial.

1.1 Definition and Purpose

Machine screws are threaded fasteners designed to secure parts in machinery and mechanical systems. Their purpose is to create strong, permanent joints between components. Available in various materials and sizes, they are engineered for durability and precision, ensuring reliable performance in diverse applications.

1.2 Brief History of Machine Screws

The origins of machine screws trace back to the Industrial Revolution, where standardized fasteners became essential for machinery. Over time, advancements in manufacturing led to precise sizing and interchangeable parts. Today, machine screws are a cornerstone in modern engineering, with sizes and materials refined for optimal performance across industries.

Understanding Machine Screw Sizes

Machine screw sizes are standardized to ensure compatibility and reliability. They are measured by diameter, length, and thread pitch, with specifications varying to suit different applications and industries.

2.1 Standard Screw Sizes

Standard screw sizes are universally recognized measurements ensuring compatibility across manufacturers. They include metric and imperial systems, with common diameters like M3, M5, and #6-32. These standards are essential for consistency and reliability in mechanical applications, helping to simplify selection and installation processes for engineers and technicians worldwide.

2.2 Diameter and Length Specifications

Diameter and length are critical dimensions for machine screws. The diameter determines the screw’s strength and fit, while the length ensures proper engagement. Specifications vary widely, from fine threads for precision applications to coarse threads for quick assembly. Accurate measurements are vital to ensure secure and reliable fastening in any mechanical system or component.

2.3 Thread Count and Pitch

Thread count and pitch are crucial for machine screw functionality. Thread count (TPI) measures threads per inch, while pitch is the distance between thread peaks. Fine threads (higher TPI, smaller pitch) offer strength and vibration resistance, ideal for tough materials. Coarse threads (lower TPI, larger pitch) enable quick assembly and are suitable for brittle materials. Proper thread alignment ensures maximum holding power and durability in various applications, depending on material and environmental conditions.

Types of Machine Screws

Machine screws come in various types, each designed for specific applications. Common types include flat head, round head, and pan head screws, suited for different design needs.

3.1 Flat Head Machine Screws

Flat head machine screws feature a flat, countersunk head, allowing them to sit flush with the material’s surface. They are ideal for applications requiring a smooth finish and minimal protrusion. Typically made from steel, stainless steel, or brass, these screws are commonly used in construction, furniture, and automotive industries for their versatility and strength.

3.2 Round Head Machine Screws

Round head machine screws have a rounded top and are ideal for applications where a flush finish is not required. They are highly versatile and commonly used in machinery, electronics, and construction. Available in materials like steel, stainless steel, and brass, these screws offer durability and are suitable for various environments and load requirements.

3.3 Pan Head Machine Screws

Pan head machine screws feature a flat, rounded head with short vertical sides, providing a large bearing surface. They are ideal for applications requiring a low-profile fastener. Commonly used in sheet metal and plastic, these screws are available in various materials. Their design ensures secure fastening and resistance to tampering, making them suitable for both light and heavy-duty applications.

3.4 Other Specialized Types

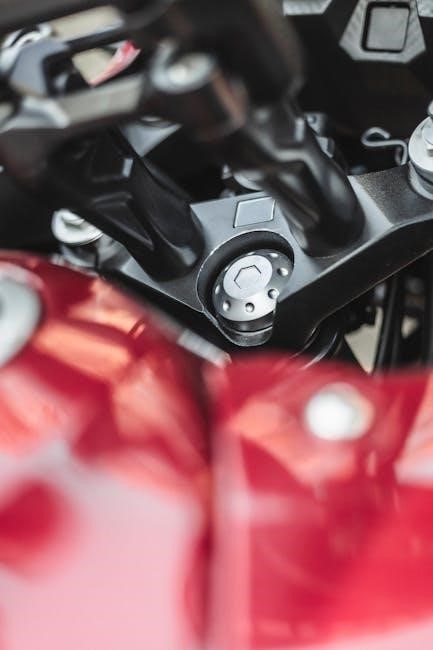

Specialized machine screws include truss, fillister, and button head types. Truss heads offer tamper resistance, while fillister heads provide a flush surface. Button heads are low-profile and countersunk. Security screws, like Torx or pin-in, prevent unauthorized access. Materials like stainless steel or brass enhance durability and conductivity, making them ideal for unique applications in electronics or heavy machinery.

Materials and Finishes

Machine screws are made from materials like steel, stainless steel, brass, and nylon. Common finishes include zinc, chrome, and nickel for corrosion resistance and durability.

4.1 Common Materials Used

Machine screws are typically made from steel, stainless steel, brass, or nylon. Steel offers strength and durability, while stainless steel provides corrosion resistance. Brass is ideal for electrical applications, and nylon is lightweight and corrosion-resistant, making it suitable for various environments and ensuring optimal performance in diverse industrial settings.

4.2 Plating and Coating Options

Machine screws often undergo plating or coating to enhance durability and corrosion resistance. Common options include zinc plating, chrome plating, and powder coating. These finishes protect the screw from environmental factors and ensure longevity in various applications, making them suitable for both indoor and outdoor use.

How to Read Machine Screw Size Charts

Understanding screw size charts involves interpreting designations, major/minor diameters, and thread counts. Accurate reading ensures correct screw selection for specific applications, optimizing performance and safety.

5.1 Understanding Screw Size Designations

Machine screw size designations include diameter, thread count, and pitch. The system specifies major diameter, threads per inch, and pitch in inches. For example, a 10-24 screw has a #10 diameter and 24 threads per inch. Understanding these designations ensures proper screw selection and compatibility for specific applications, adhering to SAE or ISO standards.

Tolerances in machine screw size charts ensure fitment consistency. They define acceptable size variations, preventing assembly issues. Proper tolerances guarantee screws mate securely without over-tightening, reducing risk of damage. Using tolerances ensures reliability and performance, especially in critical applications where precision is vital for safety and functionality, aligning with ISO or SAE standards for optimal results.

Applications and Industries

5.2 Importance of Tolerances

Tolerances ensure proper fitment and functionality. They define acceptable size variations, preventing assembly issues. Proper tolerances minimize over-tightening risks and ensure screws mate securely, enhancing reliability and safety in critical applications, adhering to ISO or SAE standards for optimal performance and consistency across industries.

6.1 Automotive Industry

Machine screws are widely used in automotive manufacturing for assembling engines, chassis, and other components. They ensure durability and safety in vehicles. Accurate sizing is critical for performance and reliability, with materials like stainless steel and zinc-plated options providing corrosion resistance. Proper screw selection enhances vehicle longevity and operational efficiency, meeting stringent industry standards and safety regulations.

6.2 Aerospace Applications

Machine screws play a critical role in aerospace engineering, ensuring the structural integrity of aircraft and spacecraft. High-strength, lightweight materials like titanium and stainless steel are commonly used. They are employed in engines, control systems, and other vital components. Precise sizing and corrosion resistance are essential for reliability in extreme environments.

6.3 Electronics and Manufacturing

Machine screws are vital in electronics and manufacturing for assembling circuit boards, devices, and machinery. They ensure secure connections and durability. Common materials include brass and plated steel, offering resistance to corrosion. Proper sizing and thread pitch are critical for precise fitment in compact electronic components and industrial equipment.

Installation Best Practices

Proper alignment and torque are critical during installation. Always use recommended tools to avoid stripping threads. Ensure screws are tightened evenly, avoiding over-tightening, for secure and durable fastening.

7.1 Choosing the Right Tools

Using the correct screwdriver or hex key ensures proper installation. Select tools that match the screw head type and size to prevent stripping. Torque wrenches are essential for applying precise force, while screw extractors can remove damaged screws. Always use tools compatible with the screw material to avoid corrosion or wear.

7.2 Techniques for Secure Fastening

Apply even torque to avoid stripping threads. Align screws properly to prevent cross-threading. Use threadlockers for added vibration resistance. Avoid over-tightening, which can damage materials. Start with low torque and gradually increase to ensure secure fastening without compromising the screw or material integrity.

7.3 Common Mistakes to Avoid

Critical common mistakes include over-tightening, which can strip threads or damage materials. Using incorrect screw sizes leads to poor fit and functionality. Ignoring thread pitch and count affects compatibility and holding power. Forgetting lubrication causes friction and wear. Improper alignment results in cross-threading or uneven stress distribution. Avoiding these ensures reliable fastening.

Metric vs. Imperial Screw Sizes

Metric screws use millimeters, while Imperial screws use inches. Metric is standardized globally, while Imperial is more common in the U.S. Understanding their differences is crucial.

8.1 Key Differences

The metric system measures screws in millimeters, emphasizing diameters and pitches in coarse or fine threads. Imperial uses inches, with unified thread standards. Metric is globally standardized, while Imperial is mainly used in the U.S. Thread pitch and diameter vary significantly between the two systems, requiring careful selection for compatibility.

8.2 Conversion Between Systems

Converting between metric and imperial screw sizes involves precise calculations. Metric diameters are converted to inches using division by 25.4. Thread pitch requires specific formulas or conversion charts. Online tools simplify this process, ensuring accuracy and compatibility. Proper conversion prevents assembly issues and ensures screws fit seamlessly across different systems and applications.

Torque and Tension Specifications

Torque and tension are critical for proper screw installation. Torque applies rotational force, while tension refers to axial force in the screw. Proper torque ensures secure fastening without over-tightening, which can damage threads or strip heads. Torque requirements vary with screw size, material, and thread pitch. Exceeding specifications risks stripping or breaking the screw, emphasizing the need for precise control and correct tools like torque wrenches to avoid common mistakes and ensure safety and reliability in applications. Always follow manufacturer guidelines to maintain structural integrity and prevent failures, making torque and tension essential considerations in machine screw selection and installation processes.

9.1 Understanding Torque Requirements

Torque refers to the rotational force applied when tightening screws. Proper torque ensures secure fastening without over-tightening, which can damage threads or strip screw heads. Torque requirements depend on screw size, material, and thread pitch. Always refer to manufacturer guidelines for specific torque values to prevent damage and ensure optimal performance and safety in applications.

9.2 Relationship Between Torque and Screw Size

Larger screws typically require higher torque for secure fastening due to increased diameter and thread count. Smaller screws need less torque to avoid damage. Always align torque with screw size specifications to ensure proper clamping force without risking thread stripping or material deformation, ensuring reliability and safety in mechanical applications and assemblies.

Common Mistakes in Screw Selection

Common errors include over-tightening, using incorrect materials, and ignoring thread pitch, leading to stripped threads or corrosion. Proper selection is vital for safety and durability.

10.1 Over-Tightening and Stripping Threads

Over-tightening machine screws can strip threads, damaging materials and reducing hold. Using torque wrenches and adhering to specified limits prevents this. Proper lubrication also helps, ensuring screws are securely fastened without excessive force, which can lead to costly repairs and compromised structural integrity in machinery and equipment.

10.2 Using the Wrong Material for the Environment

Using machine screws made from materials unsuitable for the operating environment can lead to corrosion, wear, or failure. For example, steel screws in corrosive settings may rust, while plastics may degrade under heat. Always choose materials compatible with temperature, humidity, and chemical exposure to ensure long-term reliability and safety in applications.

10.3 Ignoring Thread Pitch and Count

Ignoring thread pitch and count can lead to mismatched screws, causing loose connections or damage. Proper thread specification ensures compatibility and secure fastening. Always verify thread pitch and count to avoid installation issues and ensure optimal performance in mechanical applications.

Maintenance and Storage Tips

Regular cleaning and storing screws in dry conditions prevent rust. Lubrication ensures smooth assembly. Proper inspection before use guarantees functionality and avoids installation issues.

11.1 Proper Storage Conditions

Machine screws should be stored in a cool, dry environment, away from moisture and humidity. Use airtight containers or bins with tight-fitting lids to protect against dust and corrosion. Label each container for easy identification. Avoid storing screws in damp or poorly ventilated areas, as this can lead to rust. Keep containers off the floor and ensure the storage area is stable.

11.2 Cleaning and Lubrication

Clean machine screws with mild detergent and water, using a soft cloth or brush. Dry thoroughly to prevent rust. Apply a silicone-based lubricant to protect against corrosion and ensure smooth assembly. Regular cleaning and lubrication extend screw life and maintain performance in various applications.

11.3 Inspection Before Use

Inspect machine screws for visible damage, rust, or thread wear. Check head type and size, ensuring they match the driver. Verify the length and diameter against specifications. Look for proper plating or coating. Defects can lead to installation issues or structural failure, making inspection crucial for reliability and safety;

Resources and Tools

Essential tools include screwdrivers, torque wrenches, and thread gauges. Utilize manufacturer guides, online calculators, and conversion tools for accurate sizing and material selection.

12.1 Screw Size Charts and Tables

Screw size charts and tables provide detailed dimensions, thread counts, and material specs. They cover imperial and metric standards, ensuring compatibility and proper fitment. These resources help prevent sizing errors, enhancing safety and efficiency. Examples include McMaster-Carr and ISO standards, offering comprehensive guides for precise screw selection across various industries.

12.2 Online Calculators and Conversion Tools

Online calculators simplify screw size conversions and specifications. Tools like metric-to-imperial converters ensure compatibility. Thread pitch and diameter calculators aid precise selections. Resources like Bolt Depot and Engineering ToolBox offer detailed guides, reducing errors and enhancing efficiency in screw selection for various projects and industries.

12.3 Recommended Manufacturers and Suppliers

Trusted manufacturers like McMaster-Carr, Grainger, and Fastenal offer high-quality machine screws. These suppliers provide a wide range of sizes, materials, and finishes. They cater to both small-scale projects and industrial needs, ensuring reliability and precision. Their websites often feature detailed product specifications and customer support, making them top choices for professionals and hobbyists alike.

Selecting the right machine screw is crucial for project success. Understanding size, material, and application ensures optimal performance. Refer to size charts and manufacturers for best results.

13.1 Summary of Key Points

Machine screw size guides emphasize understanding screw types, sizes, materials, and installation best practices. Avoid common mistakes like over-tightening or ignoring thread pitch. Always refer to size charts and consult manufacturers for specific applications. Proper screw selection ensures safety, durability, and efficiency in machinery and mechanical systems, making it a critical step in any project.

13.2 Importance of Proper Screw Selection

Proper screw selection ensures safety, durability, and efficiency in machinery. Incorrect choices can lead to structural issues or mechanical failure. Matching screws to load requirements, environmental conditions, and material compatibility is vital. This prevents premature wear, reduces maintenance costs, and enhances overall system performance, making it a critical factor in engineering and manufacturing projects.